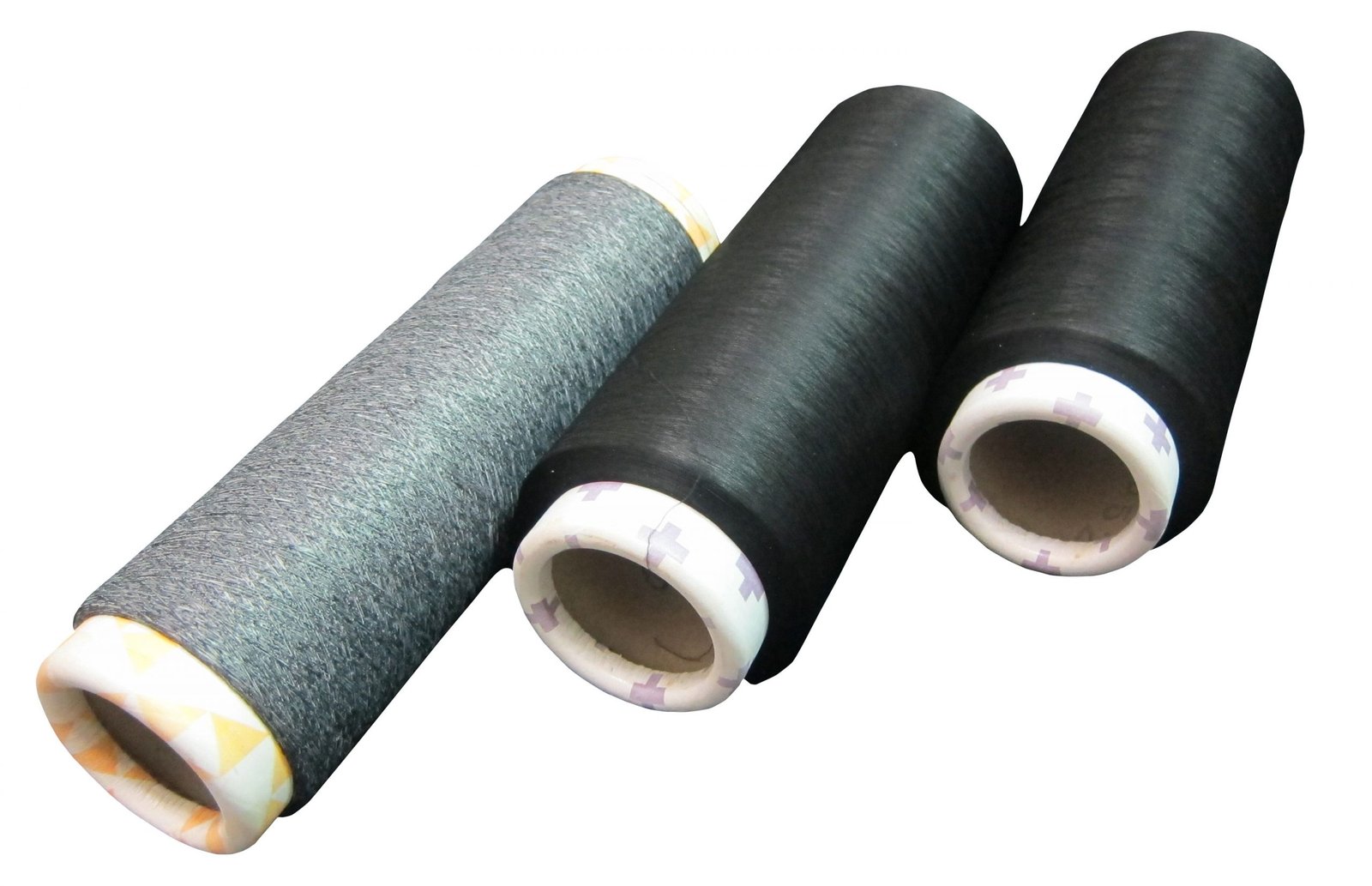

WEBTEX Conductive Fiber manufacturing process is to use the blending method and direct spinning method. The resistance impedance of the fiber in the magnetic wave shielding level is controlled below about 10¹Ω/cm, and the resistance impedance of the fiber in the conductive level is controlled around 10¹~10³Ω/cm

| Product Code | W-CON |

|---|---|

| Denier / Count / Size | Customized |

| Color | Natural Color |

| Spool of thread | Paper tube / Plastic tube / Customized |

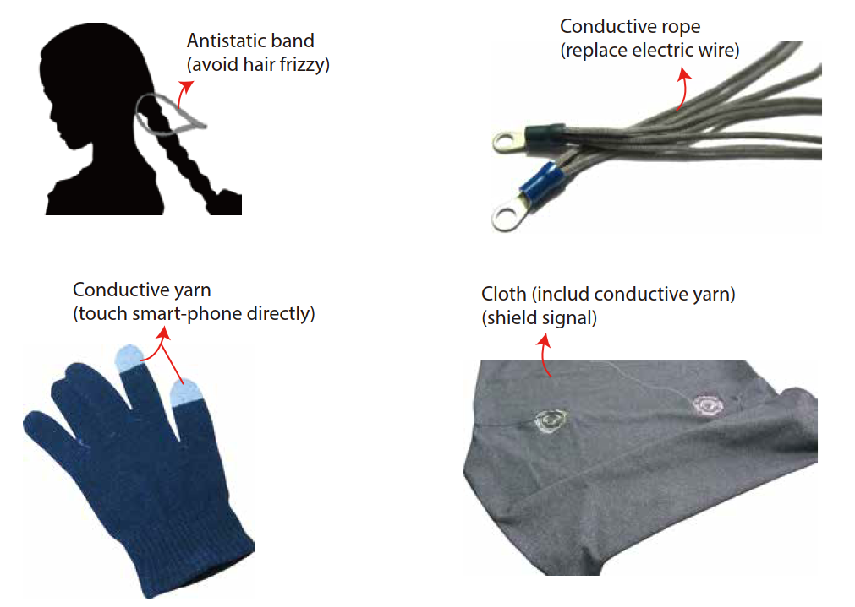

| Application | Cloth / Gloves / Clean Room / Terminal / Embroider |

| Materials | Carbon(fiber) / Stainless(fiber) / Silver(fiber) |

| Description | for different application require different materials with Ω, please advice if there is any specific demand |

| Specification | Silver fiber |

|---|---|

| Process | Used 100% Nylon, made into sheath-core composite fiber, silver particle on the sheath surface about 17-18% |

| Conductivity | 2 Ω-cm² |

| Remake | *** |

| Specification | Carbon Fiber |

|---|---|

| Process | Made by 60% PET granules and 40% PBT granules, melt spinning process |

| Conductivity | 10⁵˜⁷ Ω-cm Ω-cm² |

| Remake | *** |

| Specification | Stainless Steel fiber | ||

|---|---|---|---|

| A/S | T/S | T/C/S | |

| Process | Acrylic 87% + S/S 13%, blending | PET 80% + S/S 20%, blending | PET + Carton + S/S, blending |

| Conductivity | 10³ Ω-cm² | 10² Ω-cm² | 10 Ω-cm² |

| Remake | *** | Dyeing available | |

Application