Advantanges of WEBTEX Flame Retardant Yarn

● Phosphorus & Halongen free, eco-friendly, and Safety

● Excellent resistance to hydrolysis, permanent function of fibric flame retardance.

● Enhancing L.O.I. up to 30%

Flame Retardant Fiber Types

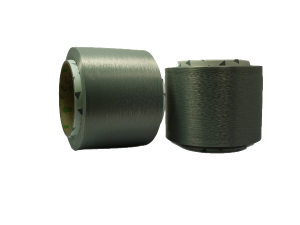

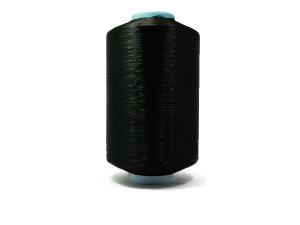

| Product Image | Product Name | Property | Colours |

|---|---|---|---|

| WEBTEX Abrasion Retardant Fiber-Nylon | Denier- 70, 200, 420 DTY, FDY | Black & Grey |

| WEBTEX Abrasion Retardant Fiber-Polyester | Denier- 70, 200, 420 DTY, FDY | Black & Grey |

L.O.I. (Limiting Oxygen Index) increased

| Nylon | Nylon with NPM-F | Polyester | Polyester with NPM-F | |

|---|---|---|---|---|

| L.O.I. | 18~20 | 32~34 | 20~22 | 32~34 |

Flame Retardant Testing Standards

● Method of Test for Flammability of Interior Materials for Automobiles CNS 13387 D3195-1994 (equal to FMVSS 302)

Result : SE (Self Extinguishing)

● Method of Test for Flammability of Textiles CNS 10285 L3196-1995 A-1

Result : Flammability : Grade 1

● Method of Test for assessment of the ignitability of upholstered seating by smouldering and flaming ignition sources BS 5858:2006 Clause 11 source 0, 1 (Cigarette, Match)

Result : NI(PASS)

NPM-F Flame Retardant Masterbatch

| Item | Specification | method | |

|---|---|---|---|

| NPM-F Nylon Masterbatch | NPM-F PET Masterbatch | ||

| Exterior | Black | Black | |

| Size | 2.5±0.1mm X 3.0±0.1mm | 2.5±0.1mm X 3.0±0.1mm | Vernier Caliper |

| Melting Point | Approx. 223°C | Approx. 258°C | ASTM D 3418 |

| Viscosity | R.V. = 2.68 ± 0.1 | I.V. = 0.65 ± 0.05 dl/g | ASTM D 789, 4603 |

APPICATIONS

● Automobile ● New juvenile prouducts ● Mattresses and Upholstered ● Textiles